Root Cause Analysis

Root Cause Analysis identifies the root cause of yield problems and provides proven solutions for yield improvement. This service is unique to BlueRing Stencils; no other stencil manufacturer offers this comprehensive value added service. In combination with decades of engineering experience, we utilize proprietary analysis software that enables BlueRing Stencils engineering team to diagnose and fix SMT yield problems anywhere in the SMT assembly process. Since the start of this service, we have performed thousands of jobs with a 98% success rate.

What do we provide?

Identify the root cause of yield problems

Accurate and thorough analysis based on assembly and process variables

Detailed and comprehensive analysis reports

Significant increases in assembly yields with specific stencil design suggestions

Areas where yield problems occur:

PCB

Component footprint

Print

Pick-and-place

Reflow profile

Wave solder

Solder paste

Thermal heat sinks

more….

Common defects that affect yields:

Poor paste release

Insufficient solder

Bridging at reflow

Tombstones

Component shift and skew

Dewetting

Solder balls

Voids

more…

Sample Reports

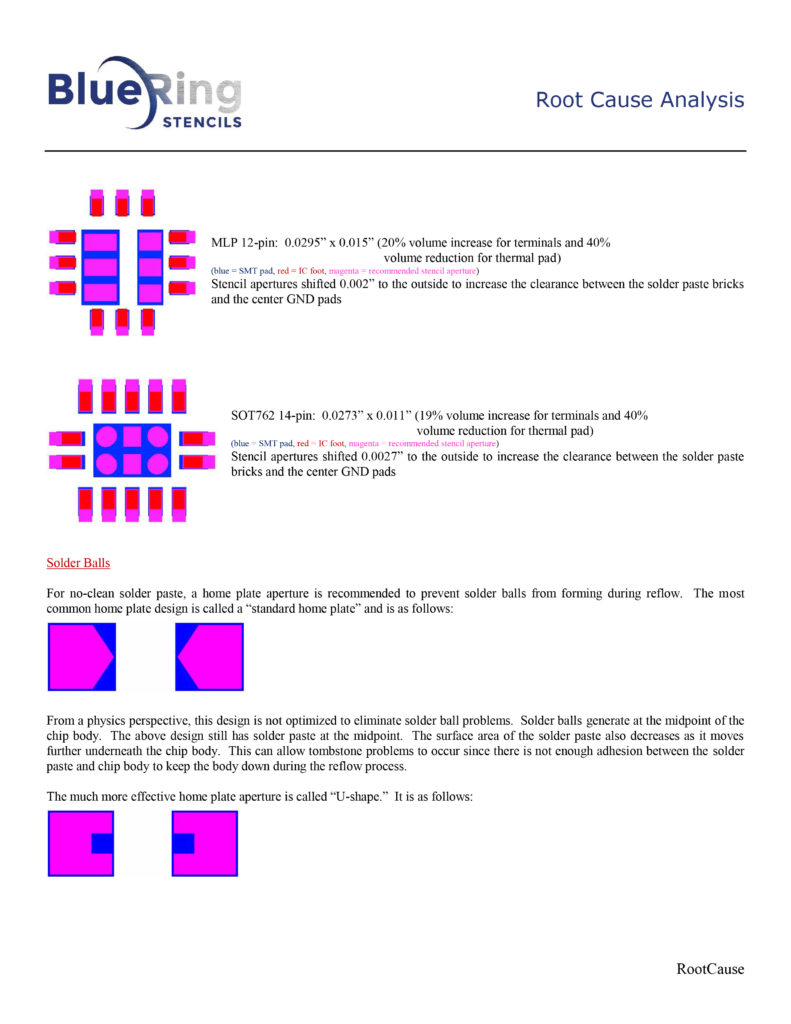

Below are sample reports which will be very similar to the one you will receive regarding your process analysis. All reports contain, the problem description, our Root Cause Analysis of the problem and our custom recommendation to solve the issue. The names have been removed to protect the identity of our clients.

Papers

Improve SMT Assembly Yields Using Root Cause Analysis in Stencil Design

Reduction of first pass defects in the SMT assembly process minimizes cost, assembly time and improves reliability. These three areas, cost, delivery and reliability determine manufacturing yields and are key in maintaining a successful and profitable assembly process. It is commonly accepted that the solder paste printing process causes the highest percentage of yield challenges in the SMT assembly process. As form factor continues to get smaller, the challenge to obtain 100% yield becomes more difficult. This paper will identify defects affecting SMT yields in the printing process and discuss their Root Cause. Outer layer copper weight and surface treatment will also be addressed as to their effect on printability. Experiments using leadless and emerging components will be studied and root cause analysis will be presented on various common SMT defects.