Micro-Milled Step Stencils

Stepped stencils, featuring localized variations in foil thickness, are designed to apply precise volumes of solder to both smaller and larger components while maintaining appropriate volumes for standard parts. These stencils have been in use for decades, but recent advancements have significantly improved the technology used to create them.

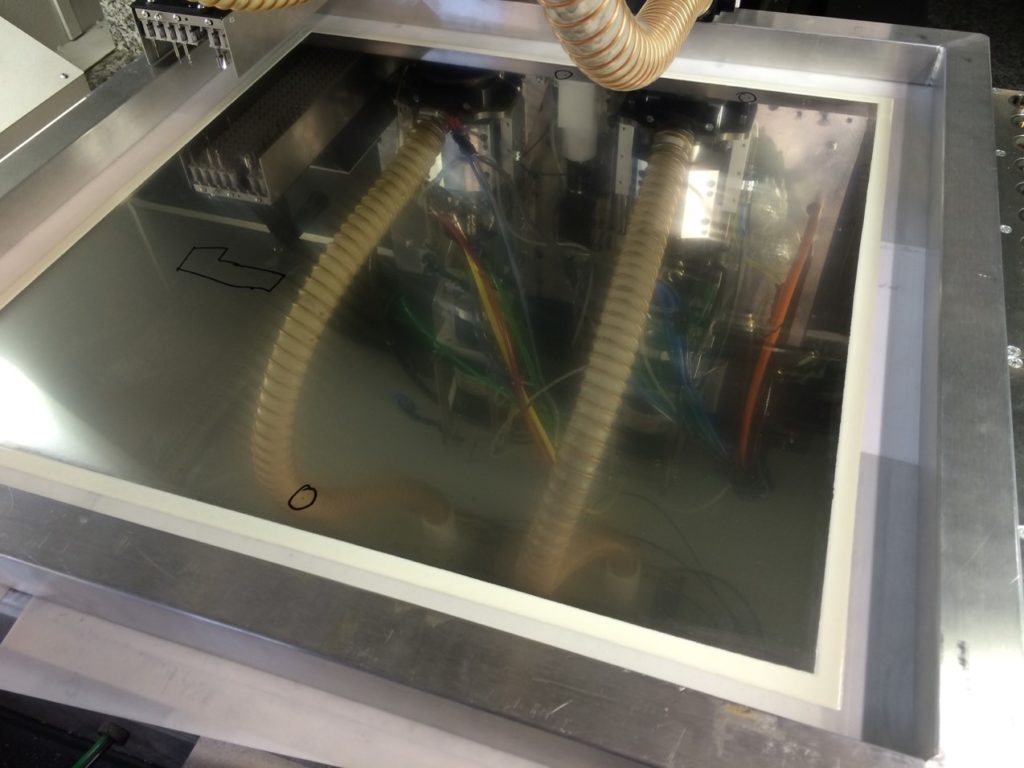

Micro-machining is one of the latest technologies employed to produce multilevel stencils for today’s demanding requirements. This process offers Z-axis accuracy of ±5 µm, enables angled step edges, and ensures a burr-free finish. Additionally, the surface roughness (Ra) of the micro-milled surface is less than 0.50 µm, comparable to the original metal.

| Process Technology | Micro-Machining | Etching | Welding |

|---|---|---|---|

| Foil Thickness Accuracy | ±5 (0.2 mils) | 127µm (0.5 mils) | ±2% Foil Thickness |

| Keep Out Zone (Per 1 mil step) | 254 µm (10 mils) | 889 µm (35 mis) | 635µm (25 mils) |

| Transition | Angled/Steps possible | 90° | Weld bead creates squeegee transition |