E-Z Step Stencils

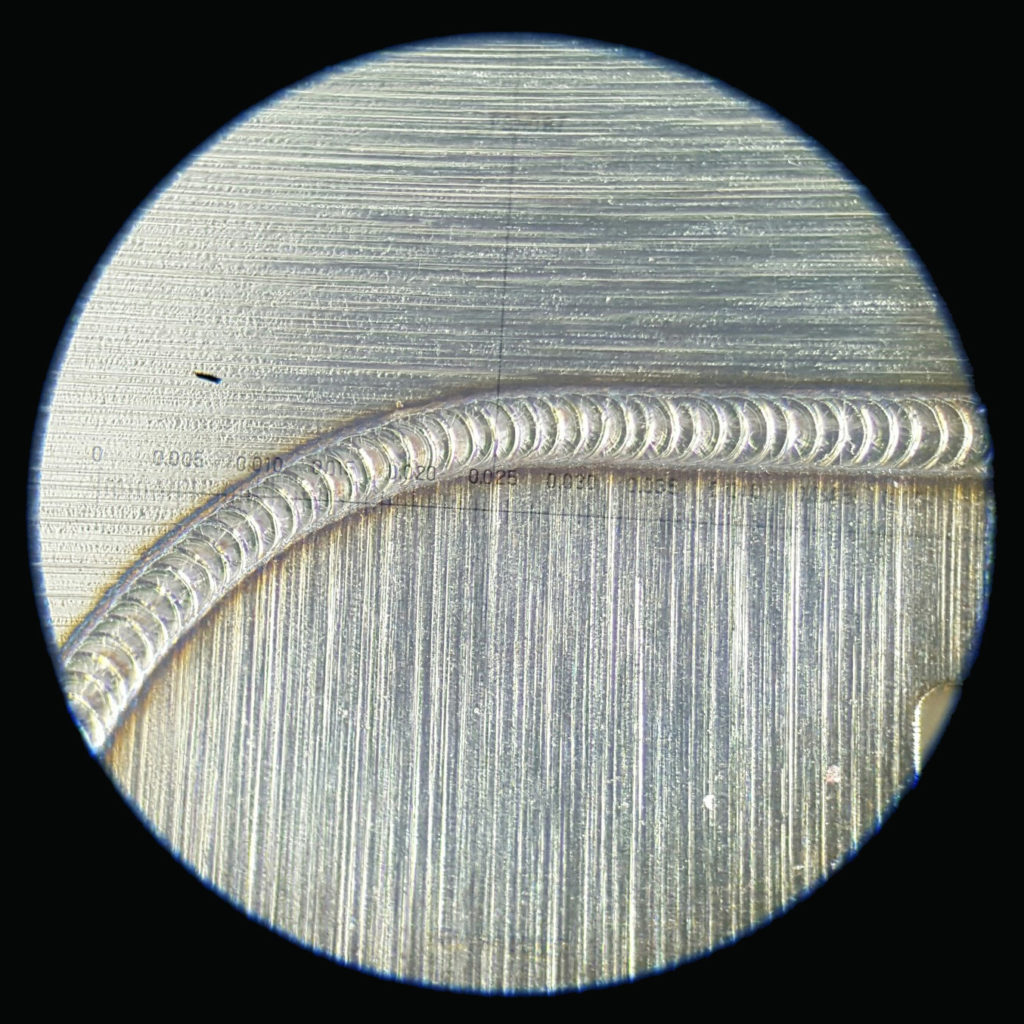

Our revolutionary E-Z Step stencils, featuring advanced laser welding, are designed to optimize solder paste volume and achieve precise brick heights on selected PCB areas. Ideal for mixed component technology, large ground pads, intrusive reflow, or areas with co-planarity issues, our stencils ensure superior performance and reliability.

Advancements in Step Technology

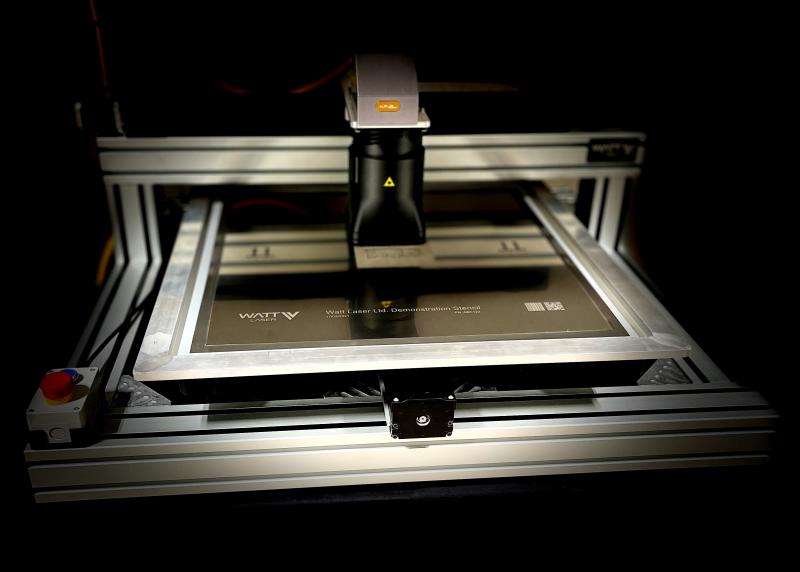

Since 2022, all BlueRing locations offer local welding services, making it easier than ever to access our top-tier stencils. At BlueRing, we prioritize innovation and quality, constantly enhancing our technology to provide a broader range of step options and stronger, flatter welds. Experience the difference with BlueRing’s cutting-edge solutions.

Partnership with Watt Laser

Top-of-the-line lasers are now available at every BlueRing location, enabling quick turnaround times for our E-Z Step Technology. Our partnership with Watt Laser Limited, a leader in surface engineering and laser materials processing, facilitates this advanced process, ensuring precision and efficiency in every stencil we produce.

| Step areas | 20 – 150 µm with support for complex shapes |

| Step ramp | Controlled step ramp in 50 µm increments |

| Positional accuracy | < 10µm on the step areas |

| Material thickness | ± 2% (primary steel and step steel) |

| Board side distortion | Flat with no impact |

| Environmentally friendly | No hazardous chemicals or pollutants used in process |

| Process | Provides increased control over your print process |

| Thickness | Vary to generate exact paste volume & height for every component |

| Lead-time | Same day quick turn service available |

Get Your Steps Locally

E-Z Step Video

Learn about how E-Z step can help solve your printing problems.