In our continued research and development of NanoSlic Gold (NSG), we explored numerous methods for increasing stencil longevity and transfer efficiency, including popular methods like Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD)

In the end, however, we discovered a method that increased stencil longevity by as much as ten times, without sacrificing transfer efficiency: Laser Direct Structuring (LDS).

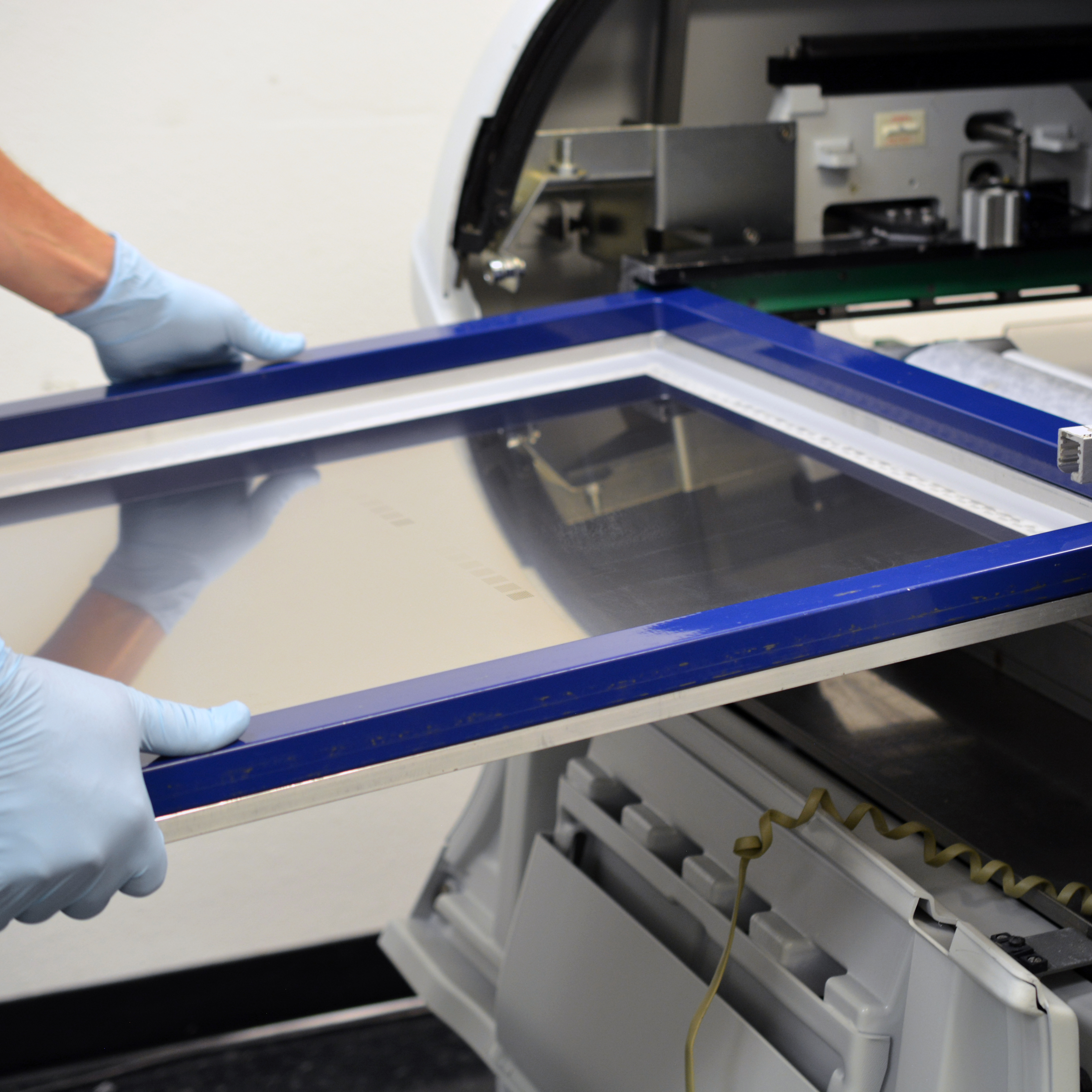

PCB Solder Stencils Specialized for High Volume Production

Our Business is Solder Stencils

BlueRing Stencils manufactures PCB solder stencils for the PCB Assembly market. Our design and assembly team has a deep understanding of the surface mount assembly process from print through reflow. BlueRing Stencils focuses our efforts and engineering staff on better understanding the entire process and designs our circuit board stencils to improve customer’s yields.

BlueRing Stencils is committed to improving technology in our market. Our advanced, state-of-the-art fiber laser cutting systems are used to produce precise SMT stencils and our NanoSlic Gold nano coating technology allows us to provide our customers with the most advanced solder stencils in the industry.

We’re engineers at ♥

SMT Laboratory

BlueRing Stencils operates a full SMT Laboratory, with SPI, Pick and Place, Reflow and X-Ray unlike any other stencil company in the United States. This distinguishing characteristic provides the ability to continuously improve both our technology and processes. NanoSlic and MicroShield, our industry changing stencil coating technologies, are both results of collaboration between our SMT Laboratory and our Polymer Chemists to develop stencil coating technologies able to print the latest ultra-small component apertures.

NanoSlic® Gold Solder Stencil Coating

The Exclusive U.S. & Canadian Licensee of NanoSlic® Gold

BRS is the only licensee in the U.S. and Canada of the Most Popular and Proven Coated Stencil in the market. The NanoSlic chemistry was not bought, it was built from the surface up. We worked closely with industry partners to develop a top of the line stencil coating. Through the use of our SMT testing lab, we were able to simulate a high production assembly environment to push the limits of NanoSlic Gold. Our lab allows us to continue research and development of new coating technologies that adapt to our customers’ rapidly evolving processes.

The NanoSlic Gold coating technology improves stencils from both a surface function and an aperture function. The most important aspect of the coating is that it’s both Hydrophobic and Oleophobic, which means the coating repels both water-based chemistry and oil-based chemistry. The result is that solder paste does not stick to the underside of the stencil even if the gasket is not perfect during the stencil print process.