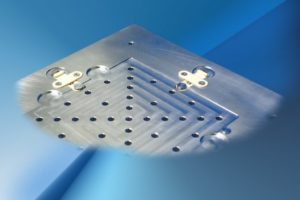

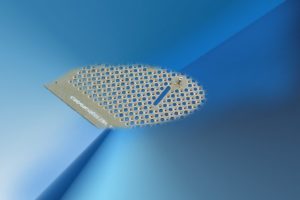

Surface Mount Carriers

Surface Mount Pallets

Successful SMT circuit carrier implementation can be an important aspect of the circuit design or array layout. BlueRing Machining is happy to review the design layout early in the circuit development process to enhance successful manufacturing processes.

Flexible and Rigid-Flex circuits, while offering many advantages, also come with unique problems that require unique solutions. We have found several ways to overcome these problems which not only help to keep the circuit in place, but also aide in keeping it flat as well.

The use of PCB tension, compression, collapsing locating pins, multiple hold-downs, tac-strips, spacers, and cantilever hold-downs are some of the methods we use for flex/rigid-flex processes to help provide precise X-Y location, and positive clamping on a stable platform for print, place, and reflow.

Exclusive “Push Away Tooling Pins” are used to locate the PCB. The use of the vacuum from your machine can be transferred through the pallet to keep the substrate on the fixture. Clamping the flex circuit for pick & place and reflow may be done with the use of a variety of different clamp designs.

The clamps can be engaged manually or automatically post screen-print on the exit rails of the printer. The circuit is precisely located and positively secured to a precise flat surface during the surface mount technology manufacturing process with pallets designed by BlueRing Machining.