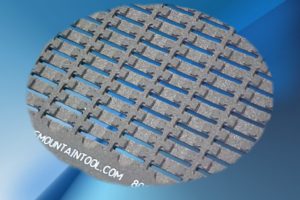

Wave Solder Pallets

Wave Solder Fixtures

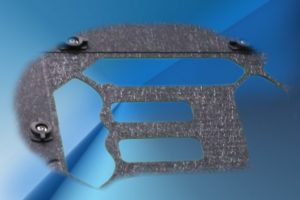

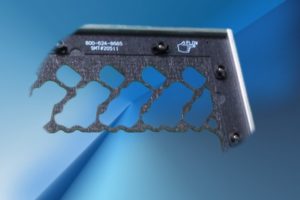

To reduce or even eliminate the costly application of liquid mask, or expensive single-use Kapton dots, Stone Mountain Tool has developed a style of masking fixtures to reach the hard to get areas and to minimize shadowing and drag out.

Sometimes during the manufacturing process, it is necessary to protect part of the circuit board, or a specific detail within the board. The application and drying time of liquid masks can be a slow and expensive process, while the use of Kapton tape is even less effective. The use of a Masking Pallet can save a great deal of valuable time and provide repeatability to the process. A masking pallet has a series of selected areas of the material left intact to support and mask specific areas of the PCB. A correctly designed pallet can cover some of the most intricate designs, large openings, ground planes, post wave connectors, mounting holes, and gold fingers. Large arrays are sometimes weakened by the amount of material removed due to routed opens in a circuit panel, causing it to sag during the thermal cycle of the solder wave. A masking fixture will help to prevent “flooding” by covering those routed opens to block solder passage and strengthen the panel to prevent scooping. This type of pallet also adds a more rigid, stable, and flatter platform for and your process.